THE AM SCREENING ( amplitude modulation )

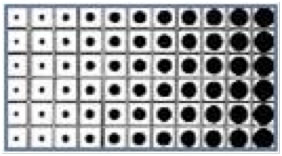

The AM SCREENING today is undoubtedly mostly employed to reproduce halftones in industrial printing technologies like Offset, typography and flexo. The AM SCREEENING is based on graphic grid where a dot stays fixed in its position in the center of any grid cell. When the density of the Halftones varies, the amplitude of the dots varies continuously accordingly the density level of the halftones. With this system you will have at low density , in the area of 5% or 10 % very small dots and improving the level of density for instance around 40-50% you will note bigger dots.

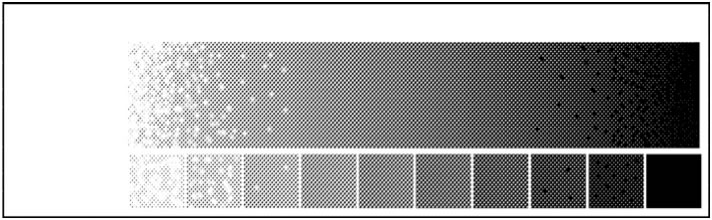

Example :

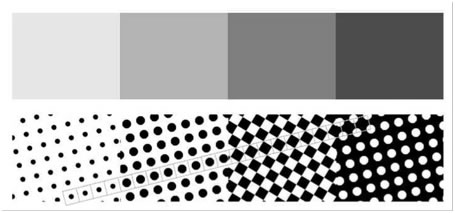

The possibilities given to the interpretation of a Halftone from the AM screening are linked to:

- The dimension of the grid cell ( usually defined as lines/inches, also known as LPI or lines/cm )

- The angle of inclination of the grid.

The shape selected for the dots placed in the center of the grid cell. So you can have round dot shape, square dot shape, elliptical dot shape , pincushion dot shape etc etc

It is clear that the AM screening is based on an orthogonal, regular and repetitive grid structure

The printing of halftone in screen printing

Whoever works in the screen printing and textile printing field is aware that any kind of photograph or image with halftones is quite “critical” for the screen printer because it is not easy to use the traditional AM screening with the screen printing technology . The actual prepress RIP software have been developed for printing technologies like offset and flexo but have never been optimized for the screen printing.

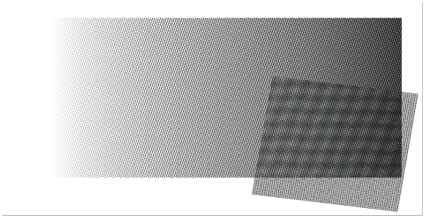

The screen printing mesh used for the screen printing process is already a repetitive and regular structure and when a film obtained through a traditional AM screening is laid upon a screen for screen printing, you get immediately the moiré effect, that is some optical interferences and visual defects defined “optically unpleasant pattern”.

Another well known problem is linked to the limit of the screen printing technique.

The screen printing in fact can print up to a limited dot dimension. If the dots to be printed are too little it is quite difficult to get in printing a stable deposition of the ink, therefore once screen printed, all the halftones are sharply cut in the lower densities and are not as continuous and soft as you would expect from looking at the positive films prepared with a imagesetter or inkjet plotter for the screen light exposition.

Moreover, in the final screen printing result of the halftones there are a very big dot gain effect in the upper part of the halftone area which is over the 60% of density. At the same time there is a progressive lack of dots in the lower part of the halftone area which is less than 20% of density.

Example of Halftone printed on a positive film ready for screen light exposition

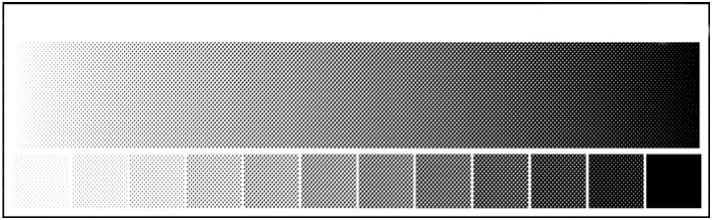

Printed result of the above Halftone at the end of a short serie of printings with thew screen printing technology

Up to now, the only solution, till now proposed, was to employ AM screenings that had very big grid cells and higher LPI up to 75-90 Lines/inch or 30-35 lines/cm . Obviously this solution reduce a lot the overall quality of the final image reproduction with the screen printing technology