Download Brochure |

|

MORE THAN 30 TYPES OF HALFTONESXerio rip has several shapes of halftone dots to meet the various requirements of screen printing, pad printing, flexo and offset.Thanks to this system you can create special halftones in order to explore in depth the various printing types which are best suited to the different substrates.Moreover, the various halftones included in the rip can be adjusted both in the angle and in the line creation, making unique screen printing films and with less moirè effect. |

|

FM STOCHASTIC SCREENING

|

|

|

|

INKJET FILM OUTPUT

|

|

|

|

||

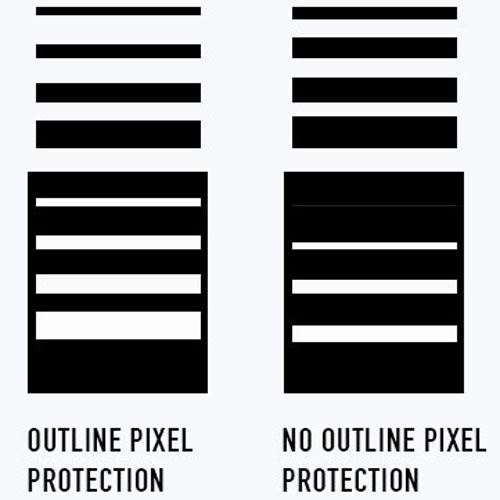

LINES AND FONTS WITH ADVANCED FUNCTIONS

XerioRIP has an advanced line control system for inkjet printing. In particular for the clichè in pad printing.In these kinds of print it is essential to check both the quality of the halftone print and the line or text produced.Our rip software has own solutions for high definition of screen printing and pad printing films that are made with the inkjet system. |

|

|

|

|

||

|

ADAVANCED SCREENING TECHNOLOGIES

|

|

Tiff output Imposition Trapping Ink duct control Stochastic Flexo Seamless INKJET output

XERIO WE o o o o o o o o

XERIO GIE o x x x x x x o

XERIO JU - x x x x x x o

XERIO J24 - x x x x x x o

XERIO J17 - x x x x x x o

o = included x= optional - = not applicable

Xerio RIP Server :

Sistema opeartivo raccomandato:

- Windows 7, Vista, XP (or newer), 64 bit

- HDD 400 Gb

- Ram 8Gb

- Processor i5

- Internet connection